WARNING: THIS WAS AN EXPERIMENTAL PROJECT AND IS BY NO MEANS A POLISHED TUTORIAL. I DID NOT DOCUMENT WELL AND DO NOT HAVE THE PIECE ANY LONGER. I CAN OFFER ADVICE AND TIPS, BUT I DO NOT HAVE TIME TO REBUILD IT AND MAKE AN IN DEPTH TUtORIAL AT THE MOMENT AND FOR THAT I APOLOGIZE.

I CANNOT RECOMMEND THAT PEOPLE DO WHAT I DID IN THE VIDEO ON YOUTUBE. DONE INCORRECTLY, IT CAN CAUSE ELECTROCUTION. (THAT MEANS YOU DIE)

Depending on the routing of the tubes on the trumpet/cornet, you will most likely have to cut the bottom off at least one of the valves. Tools you will need involve

1. Dremel with a cutoff wheel

2. Strong Fishing line/string

3. Small nut that can fit inside the trumpet and around all the corners

4. Long nose needle nose pliers or long, locking forceps

Process: (without the switch)

1. You need to take as many of the slide off as possible. then, figure out the shortest wayto get from the lead pipe to the bell.

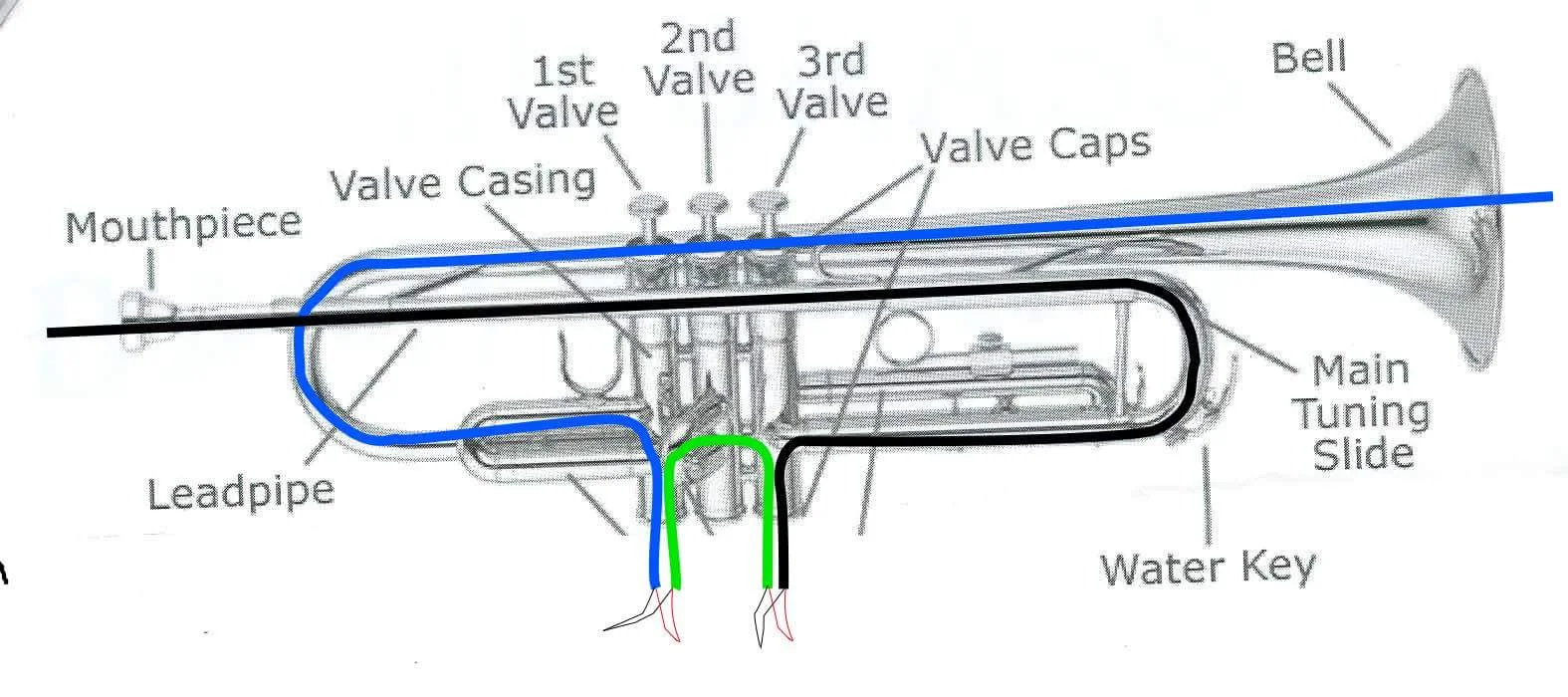

I just realized how much easier the cornet is, so I will outline the best way to do it for a trumpet in a graphic. This is all assuming no switch. Basically, you are not going to have one continuous wire through the whole trumpet, that is extremely difficult. IT is doable, but difficult.

FIRST: Take out the valves. As I said, you may have to cut the bottoms off, but you may not have to.

The wire you will use is a two sided lamp wire(the stuff you get in the lamp kit).

Tie the small nut onto the fishing line, and then use a magnet on the outside of the lead pipe to pull the fishing line through to come out the bottom of 3rd valve. Tie a the fishing line on the the wire and pull it through. make sure you tie it really tight or it will slip off. Repeat the process for the bell, but the wire will come out the bottom of first valve.

Next, you want to loop a piece of wire up 3rd, across 2nd and into the 1st valve tube. This takes a little patience and having either locking forceps or good long nose needle nose pliers works well. If it helps, you can use the same technique with the magnet and the fishing line.

Use small wire nuts or crimps to connect the wires at each pair of ends.

I can't seem to find any of my pictures save the ones I am posting right now.

SWITCH:

This is the tricky part, and dangerous part, and specifically the part I do not have any pictures of. I used a salvaged latching switch from an old stereo that was rated for 110V, and wired it up in a fashion that allowed the valve with a removed bottom to push down on the switch when depressed. This was a working, but not entirely reliable setup, as I had cut slightly too much off the valve, so it no longer had enough surface area to depress smoothly. I ended up using a bunch of dielectric grease to lubricate it. Again, I do not recommend doing this. I recommend using a lamp kit, routing the wires through the trumpet, and then using the switch on the lamp socket.